746 Products

Collection: Washdown Duty Motors

Square One Electric is where to buy Washdown Motors from top motor brands, including Baldor, Weg, Leeson, and Worldwide. Each motor ships brand new from the factory and has a manufacturer’s warranty.

Use the drop lists to narrow your selection by phase, horsepower, RPM, frame, and enclosure. Contact Us if you can’t find what you need.

What is a Washdown Motor?

Many electric motors are somewhat waterproof and designed to withstand water exposure; TEFC motors can be placed outside and hold up to the elements, such as rain. Washdown Motors, however, take it a step further; they are designed both inside and outside to hold up against frequent high-pressure washings, abrasive cleaners, and humid conditions.

There are several types of washguard motors. Depending on the application, you can buy them with white paint, no paint, and stainless steel. For example, white painted motors are cheaper than stainless, but if you are a soup company and the paint begins to chip, which could get into the product – that's a problem.

Most Washdown Motors share similar features:

- Ingress Protection, or how well the motor enclosure can keep out water against power washings. IP55, IP65, and IP66 are the most common.

- Double lip shaft seals and sealed bearings with moisture-resistant high-temperature grease.

- Ideally, the motor should have a TENV (totally enclosed non-vent) enclosure, with no internal cooling fan.

- Viton seals for chemical resistance.

- Food grade lubricants help to prevent contamination and assist with food safety.

- Encapsulated windings, or the application of additional or thicker varnish or epoxy, provide longer lifetime in humid environments.

What are Waterproof IP Ratings?

IP Ratings, or Ingress Protection Ratings, are international standards that define various levels of electrical enclosure protections against dust, dirt, moisture, and other foreign bodies. In this case, IP ratings tell how water proof a motor is.

When choosing a washguard machine, you should be familiar with the different enclosure levels. There is a large difference between water resistant and water proof. In addition, if your motors are failing at a high rate, you may want to check that the IP Rating is suitable for the application.

Here is a chart for water-related IP Ratings:

| IP Rating | Protection | Description | Test Method |

|

IP65 Enclosures |

Able to protect against water jets | Water projected by a nozzle (6.3 mm) against enclosure from any direction shall have no harmful effects. | Test duration: at least 15 minutes |

| Water volume: 12.5 litres per minute | |||

| Pressure: 30 kPa at distance of 3 m | |||

|

IP66 Enclosures |

Able to protect against powerful water jets | Water projected in powerful jets (12.5 mm nozzle) against the enclosure from any direction shall have no harmful effects. | Test duration: at least 3 minutes |

| Water volume: 100 litres per minute | |||

| Pressure: 100 kPa at distance of 3 m | |||

|

IP67 Enclsoures |

Able to protect against Immersion up to 1 m | Ingress of water in harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time (up to 1 m of submersion). | Test duration: 30 minutes |

| Immersion at depth of at least 1 m measured at bottom of device, and at least 15 cm measured at top of device |

Where are Washguard Motors Used?

Washguard motors are extremely common in the pharmaceutical and food and beverage industries, including dairy, poultry, baked goods, meat, seafood, and breweries. Essentially, any industry where product contamination is a concern, and equipment is frequently cleaned with water or solvents.

Common washdown equipment includes:

- Machine Tools

- Brakemotors

- Conveyors

- Packaging Machines

- Batching Machines

- Food and Beverage Equipment

- Washdown Jet Pumps and Pump Motors

For these companies, waterproof electric motors are key to keeping production moving without compromising product quality and safety. It is important to choose the right motor equipment in order to maintain hygiene, especially in today’s markets.

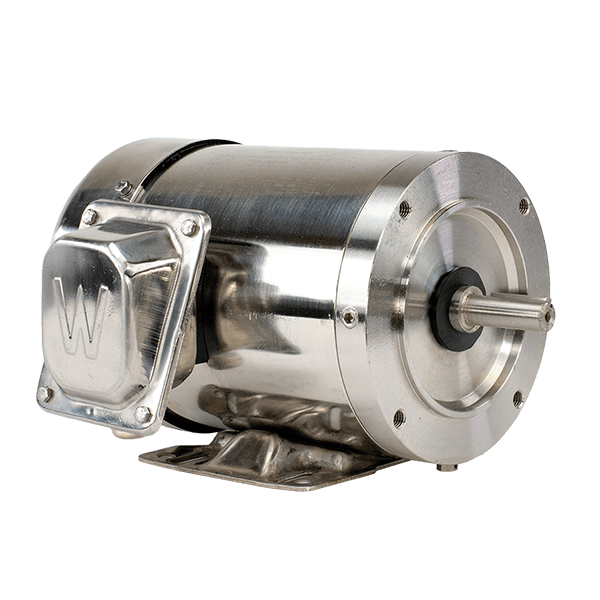

Stainless Steel Washdown Motors

Stainless steel motors are a requirement in certain applications in the US food industry. SS motors cost more than standard motors, but the investment typically pays off in the long run. As the name suggests, these machines have no paint or coating on the exterior ad are constructed mostly or completely with stainless steel.

Stainless motors can withstand frequent high-pressure cleaning without the need for protective shrouds. Equipment in sanitation areas need to be cleaned regularly, and that is when motor shroud covers become a real headache. Shrouds are designed to protect electric motors in washdown areas, but they can easily get contaminated with food particles when the fan, acting like a vacuum cleaner, sucks in air and airborne contaminants. Properly cleaning inside the shroud is time consuming and, therefore, costly.

Stainless steel motors withstand washdown conditions without the need for protective shrouds, and their popularity is growing.

Wet-food processes undergo harsh washdowns with caustic materials and high pressure and operate in humid environments. Stainless motors provide a smooth, self-draining housing without crevices where food and particles can hide, making them ideal for clean-in-place (CIP) methods.

Baldor Washdown Motors

Baldor Electric manufacturers a wide range of quality washguard equipment for all industries, and provides an impressive stock for when you need the motor now. Their washdown product line includes food safe stainless steel, paint free motors, white washdown, jet pumps, feather picker motors, brakemotors, inverter, and vector motors.

Baldor continuously works to improve their products based on industry needs, with features like an improved paint system, Baldor’s Inverter Spike Resistant insulation system, Class F insulation with Class B (or lower) temperature rise, Mobil Polyrex® EM grease, customer-friendly drain plugs, and shaft seals.

Leeson Washdown Motors

Regal Beloit provides an extensive line of waterproof machines through Leeson Electric Duck motors. They offer a solution for every level of protection:

Extreme Duck Ultra Motors

The Extreme Duck® Ultra Washdown duty motor is Regal Beloit’s ultimate solution for high-pressure and high-temperature washdowns at close range with an IP69 rating, the highest certification available for protection against solids and liquids. Additional bonus feature includes a total body encapsulation.

Premium Duck™ Motors

The Premium Duck™ motors are ideal for clean room and harsh applications involving frequent washdown with nitric acid and caustic lye. The enclosure is rated IP56 for pharmaceutical, food and beverage, chemical, and bottling industries.

SST Duck™ Motors

Paint free SST Duck™ Wash Down Duty® motors are designed for ultra-clean operations with stainless-steel external components. Example applications include food, beverage, pharmaceutical, and chemical processing.

Washguard II Motors

The Washguard® II motors are for processing areas with frequent sanitation using high pressure cleaning with caustic solutions and high humidity. Typical applications include bakeries, food processing facilities, and conveying.

White Duck™ Motors

White Duck™ motors have a high gloss, white epoxy finish for occasional washdowns. These waterproof motors are a good fit in conveying, bottling, food packaging, pump, and fan applications.