177 Products

-

Sale

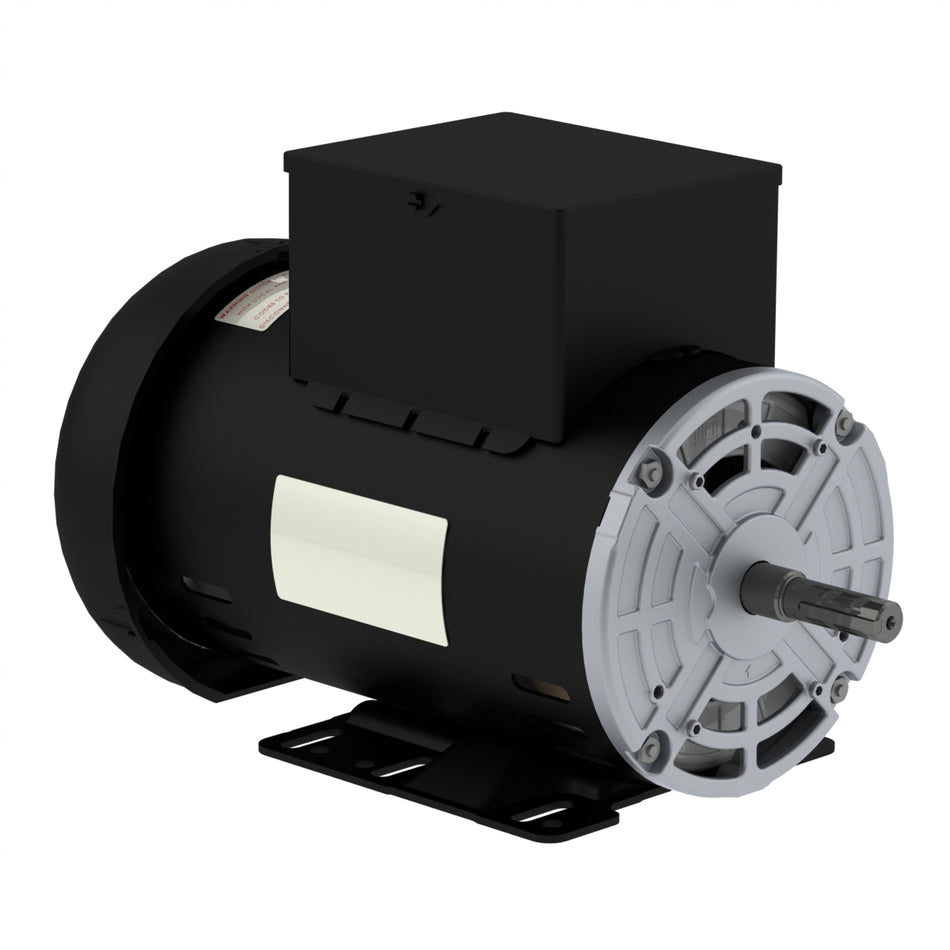

00536OS1CCDW184Y-S Weg Compressor Motor 5HP 3600RPM W182/4Y ODP 208-230Volt 1 Phase 14201573

In stockRegular price $394.50Regular price$526.00Sale price $394.50

Collection: Air Compressor Motors

Shop our online selection of air compressor electric motors from major brands including Leeson, Lincoln, Marathon, and Century. Each motor ships brands new from the factory and has a manufacturer's warranty.

Did you know that many general purpose motors are also designed for compressor applications? So, if you don't see what you need here, check out the Single Phase and Three Phase General Purpose Motor sections, or Contact Us for help.

Uses for Air Compressors

Industrial air compressors force air into a storage tank, which pressurizes the air; they run on either an electric motor, diesel, or a gas engine. Compressors have many residential, industrial, and commercial uses, including filling tires, dentistry, powering tools, ejecting production molds, and sandblasting.

Electric air compressor motors drive the machinery, and they range from light duty, portable, residential compressors to larger industrial units, like those found in construction, manufacturing, and agriculture.

Built to last, these air compressor motor replacements have a high starting and breakdown torque, durable construction, and are energy efficient.

Some OEM equipment can only be replaced from the manufacturer; our compressor motors are designed to drive a belt & pulley.

Perhaps your motor is out of stock or you want to change motor brands. We can help you find a replacement motor in your price range that gets the job done. Sqaure One is an authorized motor distributor for most major brands, some of which aren’t on our site yet.

How to Pick a Replacement Compressor Motor

When replacing an air compressor motor, look for the nameplate. It will be either a metal plate or sticker on the side for the motor. The nameplate has all the information you need for a new motor. The easiest way is to search the model, ID, or catalog number. If this doesn’t work, spec out the motor with the horsepower, frame, amperage, phase, voltage, and rotation. You may find a different brand and, if all these criteria match, then that’s fine.

Some motors are OEM (original equipment manufacturer) to the compressor company. You can likely buy the direct OEM replacement motor, but they are much more expensive than a standard stock motor. Not all OEM motors can be replaced with a stock unit, but it’s worth checking into. The new motor needs to match in horsepower, frame, amperage, phase, voltage, and rotation – if you get these matched, the new motor will bolt right in. Contact Square One Electric for help with your air compressor electric motor.

Not sure which motor to buy? Contact Square One and we can help you narrow down your options, plus provide any motor diagrams or wiring instructions.

Troubleshooting My Compressor Motor

Before you buy a new compressor motor, you might want to check the old one out first – it may be a simple fix.

If the compressor motor turns slow, or slows and stops, or just hums and won’t start, check the electrical feed to make sure it is enough. In smaller compressor units (not large industrial), using a power bar or extension cord between the compressor and outlet can reduce the power supply, and the motor isn’t getting enough feed.

Also, in single phase compressor motors, capacitors are the first thing that typically goes. Capacitors are, basically, the motor’s batteries. Some motors have one capacitor (start) and some motors have two capacitors (start and run). The capacitor typically sits on top of the motor under a cap and looks like a bump. Here are some things to check:

- Check to see if there is a connection failure. Look closely at the terminals that connect to the capacitor. Is there any rust, discoloration, loose connectors, or melted plastic? These are signs of a bad connection.

- Use a volt meter/ohm meter to check the capacitors. Do not touch the capacitor terminals with your fingers or metal objects before you discharge the capacitors and make sure there is no charge left.

- If the connections and capacitors are good, the internal contacts may need to be cleaned. At this point, if you are not skilled in motor repair, take it to your closest repair shop or contact Square One Electric.